Earthmoving Safety: Working Around Heavy Equipment

The low, resonant growl of a dozer pushing earth. The precise, powerful curl of an excavator bucket. The steady rumble of a haul truck carrying its massive load. These are the symphonies of progress, the sounds of shaping our world. But beneath this raw power lies an undeniable truth: earthmoving equipment is inherently dangerous. One moment of distraction, one skipped step in the safety operating procedures, one unrecognized hazard, and the symphony can turn tragic.

I’ve spent decades on construction sites, from blistering desert highways to muddy subdivision developments. I’ve seen the best operators – artists with hydraulic controls – and I’ve witnessed near-misses that still make my blood run cold. The difference between a productive day and a catastrophic incident often boils down to one thing: rigorous, unwavering adherence to safety operating procedures. This isn’t just about compliance; it’s about respect – respect for the machine’s power, respect for the jobsite’s complexity, and, most importantly, respect for human life. Forget the cowboy mentality; true mastery in earthmoving is measured by how safely you bring the project home. Let’s dig into what it takes to stay safe amidst these titans of industry.

What Is the Meaning of Earthmoving? More Than Just Dirt

At its core, earthmoving is exactly what it sounds like: the process of moving massive quantities of soil, rock, sand, or other earth materials. But it’s far more complex than simply shoveling dirt. It’s a fundamental phase of almost all construction and civil engineering projects, encompassing:

- Excavation: Digging foundations, trenches, basements, or reservoirs.

- Grading: Shaping the land to precise slopes and contours for roads, building pads, or landscaping.

- Hauling: Transporting excavated materials from one location to another, often over significant distances on-site.

- Compaction: Densifying soil to provide stable foundations for structures or pavements.

- Loading: Filling trucks or conveyors with excavated materials.

- Dumping/Spreading: Depositing and distributing fill material.

Think of building a highway. Earthmoving crews prepare the roadbed, cut through hills, fill in valleys, and create stable embankments. For a new skyscraper, they dig deep foundations and sculpt the surrounding terrain. It’s the literal groundwork upon which everything else is built. The scale is immense, involving massive machines moving thousands of cubic yards of material, fundamentally altering the landscape. This sheer scale is precisely why safety operating procedures are non-negotiable.

Heavy Equipment For Earthmoving: The Titans of the Terrain

Earthmoving isn’t accomplished with shovels and wheelbarrows (at least, not efficiently!). It relies on a fleet of specialized, heavy-duty machinery, each designed for specific tasks:

- Excavators: The versatile workhorses. Equipped with a boom, stick, and bucket, they excel at digging trenches, foundations, and loading trucks. Compact models work in tight spaces, while massive mining excavators move mountains. Key safety operating procedures involve strict swing radius awareness and stabilization.

- Bulldozers (Dozers): Pure pushing power. Their large, heavy blade moves vast quantities of material short distances, grades surfaces, clears land, and rips tough ground. Safety focuses heavily on visibility (especially rear blind spots) and slope operation limits.

- Wheel Loaders: The loading champions. Featuring a large front-mounted bucket, they are incredibly efficient at scooping loose material (like gravel or demolition debris) and loading trucks or stockpiles. Critical safety operating procedures include managing bucket height while traveling and avoiding overhead hazards.

- Backhoe Loaders: The compact all-rounders. Combining a loader bucket on the front and an excavator arm on the back, they are common on smaller sites for digging, loading, light dozing, and utility work. Safety requires constant switching of focus between front and rear operations.

- Motor Graders: The precision sculptors. Primarily used for fine grading, creating smooth, level surfaces with precise slopes (like roadbeds or building pads) using a long, adjustable blade. Safety operating procedures emphasize the importance of clear communication when working near other equipment or personnel due to the grader’s length and blade swing.

- Articulated Haul Trucks (Dump Trucks): The heavy haulers. Designed for off-road use, these rugged trucks transport massive loads of earth, rock, or aggregate across rough terrain. Stability on slopes, avoiding rollovers, and managing blind spots are paramount safety concerns.

- Scrapers: The self-contained earth movers. These machines cut, load, haul, and dump material in a continuous cycle using a large bowl. They are highly efficient for large-scale cut-and-fill operations. Safety requires meticulous attention to loading procedures and terrain assessment.

- Compactors: The densifiers. Rollers (vibratory, smooth drum, padfoot, pneumatic) compact soil or asphalt to achieve the required density and stability for foundations or pavements. Key safety operating procedures involve avoiding edge hazards and ensuring clear paths on slopes.

Understanding the capabilities and limitations of each machine is foundational to developing effective safety operating procedures.

Hazards in Working Around Heavy Equipment: A Landscape of Risk

An earthmoving site is a dynamic, constantly evolving environment brimming with potential dangers. Recognizing these hazards is the first critical step in mitigating them through robust safety operating procedures. We can broadly categorize them:

Mechanical Hazards – When the Machine Itself Bites

These hazards stem directly from the moving parts and operation of the equipment:

- Struck-By/Crushing Hazards: Being hit by a moving machine (especially in blind spots), pinned between equipment and fixed objects, or crushed by falling loads or equipment parts (like booms or buckets). This is arguably the most common fatal hazard in earthmoving. OSHA reports consistently identify “struck-by” incidents as a leading cause of death in construction.

- Caught-In/Between Hazards: Getting caught in rotating parts (PTO shafts, augers), entangled in hydraulic lines or tracks, or buried in trench collapses or material avalanches.

- Rollovers: Equipment tipping over, especially on slopes, uneven ground, or during sharp turns. Haul trucks and dozers are particularly susceptible. ROPS (Roll-Over Protective Structures) are life-saving, but only if used with seatbelts.

- Falling from Equipment: Slipping while mounting/dismounting, falling from platforms, or being ejected during a rollover. The “Three Points of Contact” rule is vital.

- Equipment Failure: Hydraulic hose bursts releasing high-pressure fluid, brake failure, tire explosions, or structural failure due to fatigue or overload.

Non-mechanical Hazards – The Silent Threats

These hazards aren’t directly caused by moving parts but are ever-present on the jobsite:

- Slips, Trips, and Falls: On uneven ground, muddy surfaces, debris, or ice. Constant vigilance is required.

- Noise-Induced Hearing Loss: Earthmoving equipment generates extreme noise levels (often exceeding 85-100 dB), leading to permanent damage without proper hearing protection. OSHA requires hearing conservation programs where noise exposure is significant.

- Whole-Body Vibration: Prolonged operation can lead to back injuries, circulatory problems, and fatigue. Proper seating and limiting exposure time are crucial.

- Dust and Fumes: Silica dust from cutting rock or concrete (causing silicosis), diesel particulate matter (a carcinogen), and exhaust fumes pose serious respiratory risks. Water suppression and respiratory protection are key controls.

- Extreme Weather: Heat stress, dehydration, hypothermia, and reduced visibility due to rain, snow, or fog significantly increase accident risks.

- Ergonomic Strains: Repetitive motions, awkward postures, and forceful exertions during operation or maintenance can lead to musculoskeletal disorders.

- Chemical Hazards: Exposure to fuels, lubricants, hydraulic fluids, or cleaning solvents.

Access Hazards – Getting On, Off, and Around Safely

Simply getting to and from the work position presents significant risks:

- Mounting/Dismounting: Slipping on steps or ladders, especially when wet, muddy, or icy. Jumping down instead of using steps is a common, dangerous shortcut.

- Walking Paths: Pedestrian routes intersecting with equipment travel paths create high-risk zones (“Struck-By” risks). Designated, clearly marked walkways are essential.

- Working at Height: Performing maintenance or inspections on large equipment introduces fall hazards.

- Unstable Ground: Accessing equipment on slopes, near excavations, or on freshly placed/ uncompact fill can lead to slips or ground collapse.

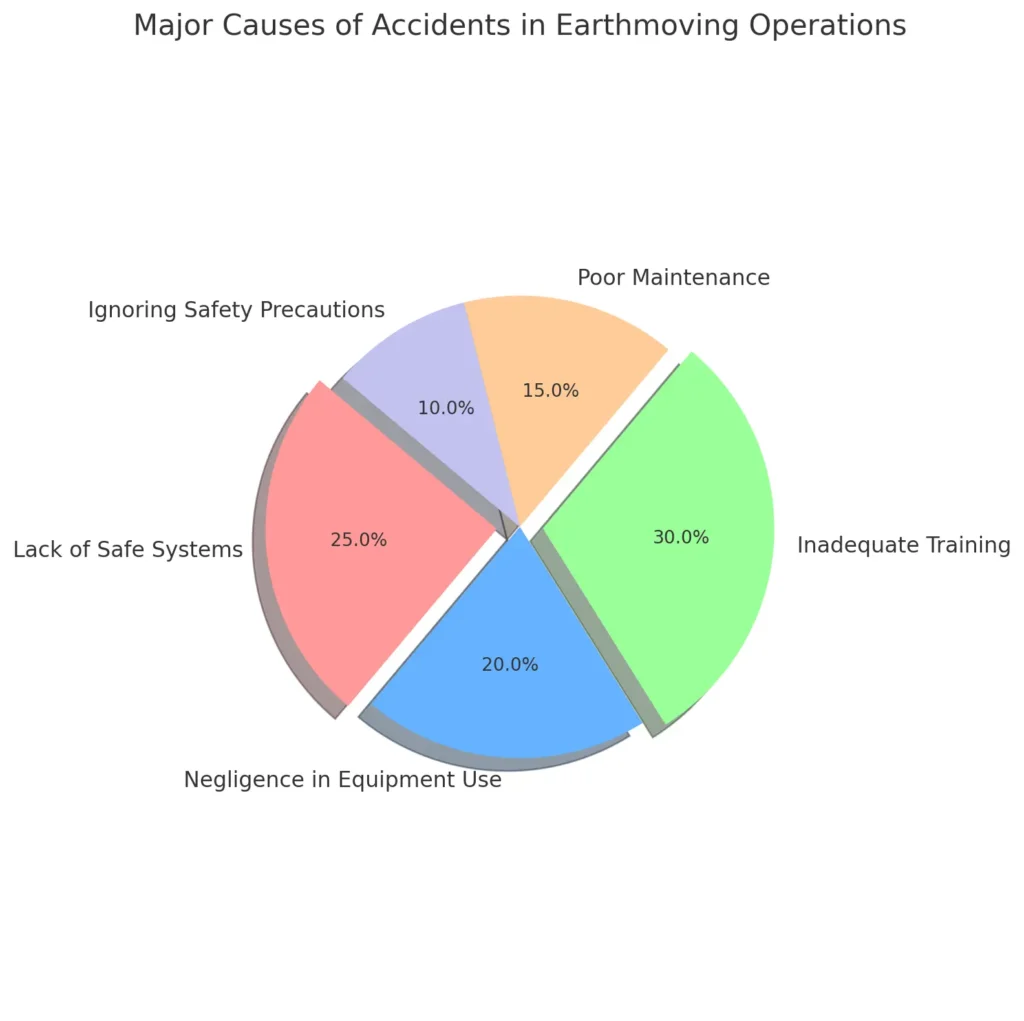

Major Causes of Accidents in Earthmoving: Why Things Go Wrong

Accidents rarely have a single cause. They are typically the result of a chain of failures, often rooted in lapses of safety operating procedures. Understanding these root causes is vital for prevention:

Lack of Safe Systems for Earthmoving Operations

- No Formal Plan: Jumping into work without a comprehensive site-specific safety plan addressing earthmoving hazards.

- Poor Traffic Management: Failing to establish and enforce clear travel paths, speed limits, loading zones, and pedestrian exclusion zones for different equipment types. This is a massive contributor to struck-by incidents.

- Inadequate Communication: Lack of standardized hand signals, radio protocols, or spotter use, especially in noisy environments or blind spot areas.

- Ignoring Site Conditions: Not adequately assessing or mitigating risks related to slopes, unstable soil, underground utilities, overhead power lines, or proximity to other workers/activities.

Negligence in the Proper Selection and Use of Equipment

- Wrong Tool for the Job: Using an excavator for a task better suited to a dozer, or overloading a machine beyond its rated capacity.

- Improper Attachment Use: Using buckets, hammers, or forks not rated for the machine or the task, or using them incorrectly.

- Ignoring Load Charts: Operating cranes or lifting loads without adhering to the manufacturer’s load charts for boom angle, radius, and configuration.

- Modification Risks: Making unauthorized modifications to equipment that compromise stability or safety systems.

Inadequate Training or Lack of Experience Among Operators

- Unqualified Operators: Allowing personnel without proper training, certification, or experience to operate complex machinery. OSHA requires operators to be certified.

- “Good Enough” Mentality: Assuming basic familiarity is sufficient without ongoing, specialized training on specific machine models and site hazards.

- Lack of Familiarity: Putting an operator on a machine type they haven’t been trained on recently or extensively.

- Ignoring Safety Features: Operators bypassing or disabling safety systems (like seatbelt interlocks, alarms, or cameras) due to complacency or perceived inconvenience.

Noncompliance with Maintenance Requirements

- Deferred Maintenance: Skipping scheduled services for brakes, hydraulics, steering, or safety systems to save time or money.

- Ignoring Pre-Start Checks: Operators failing to conduct thorough daily inspections (walk-arounds) to identify leaks, tire damage, loose fittings, or malfunctioning lights/signals.

- Using Faulty Equipment: Allowing machines with known defects (bad brakes, non-functional backup alarms, cracked ROPS) to continue operating.

- Poor Record Keeping: Not maintaining accurate maintenance logs to track service history and identify recurring issues.

Failure to Observe the Required Earthmoving Safety Precautions

- Complacency: Becoming too comfortable with the routine and letting guard down (“It won’t happen to me”).

- Rushing: Speeding up operations to meet deadlines, leading to shortcuts and reduced vigilance.

- Distraction: Using phones, engaging in non-essential conversation, or focusing on tasks other than operating safely.

- Bypassing Procedures: Ignoring lockout/tagout during maintenance, not using spotters when required, or entering exclusion zones.

- Poor Visibility Practices: Operating without ensuring clear sightlines, failing to use mirrors/cameras effectively, or not communicating with ground personnel in blind spots.

Safety Measures for Earthmoving Works: Building Your Fortress of Safety

Preventing accidents requires a systematic, multi-layered approach centered on robust safety operating procedures. Here’s how to fortify your site:

Ensure Site Security

- Perimeter Control: Fence the entire site to prevent unauthorized access by the public or untrained personnel. Use gates with access control.

- Signage: Post clear, visible signs at all entrances: “Hard Hat Area,” “High Visibility Vest Required,” “Authorized Personnel Only,” “Heavy Equipment Operating,” “Blind Spots.”

- Access Points: Designate specific, controlled entry/exit points for personnel and vehicles.

- Visitor Management: Implement a strict sign-in/sign-out and escort procedure for all visitors. Provide site-specific safety briefings.

Prepare a Safe Work Method Statement (SWMS)

- Mandatory Planning: Develop a SWMS (or Job Hazard Analysis – JHA) before earthmoving work begins. This isn’t paperwork; it’s a thought process.

- Identify Hazards: Brainstorm all potential hazards for the specific tasks and site conditions.

- Define Controls: Specify the safety operating procedures and controls to eliminate or minimize each hazard (e.g., spotters for blind zones, specific traffic routes, exclusion zones, communication protocols).

- Involve the Crew: Discuss the SWMS with everyone involved. Their input is invaluable, and their buy-in is essential.

- Review & Update: Revisit the SWMS regularly, especially if site conditions change significantly or after an incident/near-miss.

Conduct On-Site Inspections and Maintenance

- Daily Pre-Start Checks: Mandate operators perform a thorough walk-around inspection using a checklist before starting any machine. Check fluids, tires/tracks, lights/signals, brakes, steering, attachments, safety devices (ROPS/FOPS integrity, seatbelts, backup alarms).

- Document Deficiencies: Log any issues found. Tag out and remove defective equipment from service immediately until repaired by qualified mechanics.

- Preventive Maintenance: Adhere strictly to the manufacturer’s maintenance schedule. Keep meticulous records. Don’t wait for breakdowns.

- Competent Mechanics: Ensure maintenance is performed only by qualified technicians using proper procedures, tools, and Lockout/Tagout (LOTO).

Conduct Construction Induction Training

- Site-Specific Orientation: Require all personnel (employees, contractors, visitors) to undergo site-specific safety induction training before accessing the work area.

- Content: Cover site rules, emergency procedures (fire, evacuation, first aid), identified hazards, PPE requirements, designated walkways/traffic routes, communication protocols, and reporting procedures for hazards/incidents.

- Documentation: Maintain records of all training provided.

Validate the Competence of Site Personnel, Mechanics, and Operators

- Certification: Ensure all equipment operators hold valid certifications meeting OSHA requirements and manufacturer recommendations.

- Experience Verification: Check references and verify experience on specific machine types.

- Site Evaluation: Consider practical assessments for operators new to your site or specific tasks.

- Mechanic Qualifications: Verify mechanics have the appropriate training, certifications, and experience for the equipment they service.

- Ongoing Training: Provide regular refresher training on safety operating procedures, new equipment, incident learnings, and hazard recognition.

Utilize Documents for Earthmoving Safety

- Operator Manuals: Keep manufacturer operation and maintenance manuals readily available on-site and ensure operators are familiar with them. These are the bible for safety operating procedures specific to that machine.

- Load Charts: Ensure crane and lifting equipment load charts are accessible and understood by operators.

- Inspection Checklists: Use standardized, comprehensive checklists for daily inspections and periodic maintenance.

- Maintenance Logs: Maintain detailed, accurate records of all maintenance performed.

- Training Records: Document all safety training provided to personnel.

- SWMS/JHA: Ensure completed and approved SWMS documents are accessible at the work area.

- Incident Reports: Thoroughly document all incidents and near-misses to drive learning and prevention.

Stay Safe While Working With Heavy Equipment: Beyond the Operator’s Seat

Safety isn’t just the operator’s responsibility. Everyone on site – laborers, surveyors, supervisors, truck drivers – needs to be hyper-aware when working around earthmoving equipment. Here’s how:

- Assume You Are Invisible: Operate under the constant assumption the equipment operator cannot see you. Never assume they know you’re there.

- Respect Exclusion Zones: Stay outside marked danger zones around operating equipment, especially swing radii, dump zones, and blind spots. Barricades and tape are there for a reason.

- Use Designated Walkways: Never cut across equipment paths. Stick to clearly marked pedestrian routes.

- Make Eye Contact: Before approaching any equipment, ensure you have made eye contact with the operator and they have acknowledged you. Use agreed-upon hand signals if needed.

- Stay Alert, Avoid Distractions: Keep your head up and your eyes scanning. Don’t use headphones or be engrossed in your phone while moving around the site.

- Communicate Clearly: Use radios or standardized hand signals if communication is necessary with an operator. Ensure signals are understood before work begins.

- Know the Plan: Understand the site traffic management plan, loading zones, and work sequences.

- Report Hazards Immediately: If you see an unsafe condition, a near-miss, or a piece of equipment behaving erratically, report it to a supervisor immediately. Don’t wait.

How To Be Safe When Operating Earthmoving Machinery: The Operator’s Commandments

For the person at the controls, safety is a continuous, active process. Here are the core safety operating procedures every operator must live by:

Wear High-Visibility Clothing: Be Seen, Stay Safe

- Non-Negotiable PPE: High-visibility (Hi-Vis) vests or shirts meeting ANSI/ISEA 107 Class 2 or 3 standards are mandatory on virtually all construction sites. They dramatically increase your visibility to other operators and ground personnel, especially in low-light conditions, dust, or rain.

- Day & Night: Choose the appropriate class for the environment. Class 3 offers the highest visibility and is often required for high-risk areas like traffic zones. Ensure reflective strips are clean and intact.

- No Exceptions: This applies every single time you step onto the site, even if just for a quick task. Your life depends on it.

Only Let Trained Operators Use The Machinery: Certification is Key

- Legal & Moral Imperative: Operating complex earthmoving equipment without proper training and certification is illegal (per OSHA) and incredibly reckless.

- Beyond Basic Controls: Certification ensures operators understand not just how to move levers, but also the machine’s stability characteristics, load limits, safety systems, blind spots, and specific safety operating procedures for that model.

- Verify & Validate: Supervisors must rigorously check operator certifications and competence before assigning them to a machine. Never yield to pressure to put an unqualified person in the seat.

Be Aware Of Hazards Around The Machinery When In Use: Constant Vigilance

- 360-Degree Awareness: Before moving any control, know what’s happening around your machine. Use mirrors, cameras (if equipped), and physically look around. Blind spots are killers.

- Scan Continuously: Don’t just look once; keep scanning your environment constantly as you work. Be aware of changing conditions – new personnel entering the area, ground stability shifting, overhead hazards.

- Use Spotters: Whenever visibility is restricted, especially when backing up, operating near drop-offs, trenches, or close to other workers/structures, use a trained spotter. Agree on clear hand signals beforehand and maintain communication.

- Know Your Swing Radius: Excavator operators, be hyper-aware of your boom’s swing radius. Mark exclusion zones on the ground if possible.

- Watch for Overheads: Always be conscious of power lines, structures, trees, and other overhead obstructions. Maintain safe clearance distances mandated by OSHA.

- Ground Conditions: Continuously assess the ground for stability, especially on slopes, near excavations, or after weather events. Watch for hidden obstacles.

Check Maximum Load Limits: Don’t Push the Envelope

- Respect the Chart: Every loader, crane, and lifting machine has a load chart specifying its safe lifting capacities based on boom length, angle, radius, and configuration. MEMORIZE it. CONSULT it constantly. Never exceed these limits.

- Stability is Paramount: Overloading drastically reduces stability, increasing the risk of tip-overs, structural failure, or loss of control. Consider the weight of attachments (buckets, hammers).

- Center of Gravity: Load trucks and equipment evenly and securely. Unbalanced loads are unstable loads. Know the machine’s load center.

- When in Doubt, Don’t Lift: If a lift feels unstable or you’re unsure about the weight, STOP. Seek guidance. Don’t guess.

Check For Blindspots: Know What You Can’t See

- Every Machine Has Them: Understand the specific blind spots for the equipment you’re operating. These are typically directly behind, along the sides (especially near the cab), and sometimes low to the ground in front. Study diagrams in the operator’s manual.

- Mirrors & Cameras: Adjust mirrors correctly before starting work and use them constantly. If equipped with cameras, use them, but remember they are aids, not replacements for looking.

- The “Look Before You Move” Rule: Always look in the direction of travel before moving the machine, especially reversing. Do a full sweep.

- Communicate Intentions: Use horns or backup alarms (ensure they are working!) before moving. Signal your intentions to nearby workers.

- Spotters Are Essential: In congested areas or when visibility is poor, a competent spotter is your best defense against blind spot accidents.

Load Machinery On Level Ground: Stability First

- Critical for Stability: Loading buckets, lifting materials, or handling heavy loads should always be done on firm, level ground whenever possible.

- Reduces Tip Risk: Operating attachments or lifting on a slope significantly shifts the machine’s center of gravity, increasing the risk of a rollover.

- Prevents Dropped Loads: Uneven ground can cause the machine to shift unexpectedly, leading to loss of control of the load.

- If Slopes Are Unavoidable: Follow manufacturer guidelines strictly for operating on slopes. Position the machine correctly (e.g., excavators with tracks perpendicular to the slope). Exercise extreme caution and reduce speed. Avoid lifting or loading near the edge of slopes.

Preparing For Summer: The Importance Of Vehicle Air Conditioning Maintenance

While not directly part of core earthmoving safety operating procedures, operator comfort is intrinsically linked to safety, especially in extreme heat:

- Heat Stress is a Hazard: Operating heavy machinery in a hot cab is exhausting and leads to dehydration, fatigue, impaired judgment, and heat stroke – all major safety risks.

- AC is a Safety System: A functioning air conditioning system is vital for maintaining operator alertness, comfort, and cognitive function during long, hot shifts. Treat it as essential safety equipment.

- Pre-Season Check: Before summer hits, get the AC system professionally inspected. Check refrigerant levels, compressor function, condenser/evaporator cleanliness, and belt tension.

- Regular Maintenance: Include AC checks in routine maintenance schedules. Clogged filters or low refrigerant significantly reduce performance.

- Operator Awareness: Encourage operators to report AC issues immediately. Provide ample water and encourage frequent breaks in shaded or cool areas.

The Importance of Regular Air Conditioning Maintenance in Vehicles

Building on the seasonal point:

- Prevents Major Failures: Regular checks can identify small leaks, worn components, or electrical issues before they lead to a complete system failure during a critical time.

- Maintains Efficiency: A well-maintained AC system cools more effectively and uses less fuel.

- Air Quality: Clean filters prevent dust, pollen, and pollutants from entering the cab, protecting operator respiratory health, especially important in dusty earthmoving environments.

- System Longevity: Proactive maintenance extends the life of expensive AC components.

How To Choose The Right Truck Auto Electrician For Your Fleet

Electrical systems are the nervous system of modern earthmoving equipment. Choosing the right mechanic is crucial:

- Heavy Equipment Specialization: Don’t use your local car mechanic. Seek technicians specifically trained and experienced with the complex electrical, hydraulic, and computerized systems of heavy off-road equipment (Caterpillar, Komatsu, John Deere, Volvo CE, etc.).

- Certifications: Look for ASE (Automotive Service Excellence) certifications, especially in Medium/Heavy Truck (series) and Electrical/Electronic Systems (A6). Manufacturer-specific certifications (like CAT ET, Deere Service Advisor) are a huge plus.

- Diagnostic Capability: Modern machines have sophisticated ECMs (Engine Control Modules) and multiplexed wiring. The technician must have advanced diagnostic tools and the skills to interpret fault codes and wiring diagrams.

- Reputation & References: Ask other contractors or equipment dealers for recommendations. Check online reviews.

- Mobile Service vs. Shop: Consider if you need a mobile technician who comes to your site or a dedicated shop. Mobile is convenient but may have limitations on major repairs.

- Preventive Maintenance Focus: Choose a provider who emphasizes proactive maintenance to prevent electrical failures, not just fixing breakdowns. Ask about their PM programs.

FAQs: Demystifying Safety Operating Procedures

What is a safe operation procedure (SOP)?

A Safe Operating Procedure (SOP) is a step-by-step, written instruction detailing how to perform a specific task or operate a particular piece of equipment safely. It outlines the hazards involved and the controls required to minimize risks. In earthmoving, SOPs cover everything from daily equipment inspections to specific digging or loading techniques. They are the foundation of consistent safety operating procedures.

What are the five standard operating procedures?

While formats vary, robust SOPs generally include these five key elements:

- Purpose & Scope: Clearly state what task/equipment the SOP covers and its objectives.

- Responsibilities: Define who is responsible for performing, supervising, and maintaining the procedure.

- Hazards & Controls: Identify all potential hazards associated with the task and specify the exact controls (PPE, engineering controls, administrative procedures) required to mitigate them.

- Step-by-Step Instructions: Provide a clear, sequential list of actions to perform the task safely. Use plain language and diagrams/photos if helpful.

- Emergency Procedures & References: Outline what to do if something goes wrong (e.g., equipment malfunction, injury) and list any relevant regulations, standards, or manuals.

How to write a safe operating procedure?

- Identify the Task: Define the specific process or equipment operation.

- Assemble a Team: Involve experienced workers, supervisors, and safety personnel.

- Break Down the Steps: List every step involved in the task sequentially.

- Identify Hazards: For each step, brainstorm potential hazards (mechanical, non-mechanical, access).

- Determine Controls: Specify the exact safety operating procedures and controls needed to eliminate or minimize each hazard (e.g., LOTO, PPE, spotters, specific techniques).

- Draft the SOP: Write clearly and concisely using the 5-element structure above. Use bullet points, numbered steps, and visuals.

- Review & Test: Have the team and end-users review the draft. Test it in the field if possible. Refine.

- Train & Implement: Train all affected personnel on the new SOP. Make it easily accessible.

- Review & Update: Regularly review and update SOPs based on experience, incidents, new equipment, or changing regulations.

What are safe work procedures (SWPs)?

Safe Work Procedures (SWPs) are essentially synonymous with Safe Operating Procedures (SOPs). They are documented methods outlining how to perform work safely, identifying hazards and required controls. The term “SWP” might be used more broadly to encompass non-equipment tasks, while “SOP” often refers specifically to equipment operation, but the core purpose is identical: ensuring tasks are performed safely through defined safety operating procedures.

What is PPE in safety?

PPE stands for Personal Protective Equipment. It is equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. In earthmoving, common PPE includes:

- Hard Hat: Protects from falling objects and head impacts.

- Safety Glasses/Goggles: Shield eyes from dust, flying debris, and chemicals.

- Hearing Protection (Earplugs/Muffs): Reduces exposure to damaging noise levels.

- Hi-Visibility Clothing: Makes the wearer more visible to equipment operators.

- Safety Boots (Steel/Composite Toe): Protects feet from crushing injuries, punctures, and slips.

- Gloves: Protect hands from cuts, abrasions, chemicals, and vibration (anti-vibration gloves).

- Respirators: Protect against dust (silica), fumes, and other airborne contaminants when engineering controls aren’t sufficient. PPE is the last line of defense, used when hazards cannot be fully eliminated by other means.

What are safety protocols?

Safety protocols are established, formal sets of rules or procedures designed to ensure safety in specific situations or environments. They dictate how safety measures should be implemented and followed. Examples relevant to earthmoving include:

- Lockout/Tagout (LOTO) Protocol: The specific steps for de-energizing and securing equipment during maintenance.

- Confined Space Entry Protocol: Procedures for safely entering and working in tanks, silos, or trenches.

- Traffic Management Protocol: Rules for equipment movement, pedestrian routes, and communication on site.

- Emergency Response Protocol: Steps to follow in case of fire, injury, collapse, or hazardous spill.

- Communication Protocol: Standardized hand signals or radio procedures. Safety protocols operationalize safety operating procedures for specific scenarios.

What are the 5 types of safety?

Safety is often categorized into different types or domains, especially in occupational health and safety (OHS). Five common types are:

- Physical Safety: Protecting workers from physical hazards like moving machinery, falls, electricity, noise, extreme temperatures, and radiation. This is the primary focus in earthmoving safety operating procedures.

- Chemical Safety: Protecting workers from exposure to hazardous chemicals (fuels, solvents, cleaners, dusts like silica) through proper handling, storage, labeling, ventilation, and PPE.

- Biological Safety: Protecting workers from biological hazards (bacteria, viruses, fungi, mold, insects, animal waste) – less common in core earthmoving but relevant in demolition or site clearing near water.

- Ergonomic Safety: Designing workstations, tools, and tasks to fit the worker and minimize risk of musculoskeletal disorders (repetitive strain, back injuries) – crucial for operators spending long hours in cabs.

- Psychological Safety: Creating a work environment where workers feel safe to speak up about concerns, report errors or near-misses without fear of punishment, and feel respected and supported. This underpins a strong safety culture where safety operating procedures are genuinely followed.

The Final Scoop: Safety is the Foundation

Earthmoving shapes our world, but it demands profound respect. The power of these machines is awe-inspiring, but it’s the disciplined application of safety operating procedures that allows us to harness that power without paying a terrible price. From the meticulous planning of a SWMS to the operator’s constant vigilance in their cab, from the mechanic’s precise wrench turn to the laborer sticking to the walkway – every action grounded in safety builds a stronger, more resilient worksite.

It’s not about slowing down; it’s about ensuring everyone goes home. It’s not about bureaucracy; it’s about the lived experience that every procedure, every check, every piece of PPE, is a lifeline. The most productive sites I’ve ever worked on weren’t the most chaotic; they were the ones where safety was the bedrock, the shared language, the non-negotiable commitment.

What’s your biggest challenge or success story implementing safety operating procedures on your earthmoving site? Share your experiences and insights in the comments below – let’s learn from each other and build a safer industry together. Explore more deep dives into construction safety protocols on our blog! https://alliedrentalmachines.com/blog/ Stay safe out there!