Top 7 Types of Cranes You Should Consider Renting in 2025

The construction industry is experiencing unprecedented growth in 2025, with infrastructure projects, commercial developments, and residential construction reaching new heights across the United States. Behind this boom stands an essential yet often overlooked hero: the crane. As projects grow in complexity and scale, selecting the right type of crane has become more crucial than ever for contractors and project managers aiming to maximize efficiency while minimizing costs.

Crane rental decisions directly impact not only your project timeline and budget but also workplace safety and environmental footprint. The right crane can mean the difference between a project completed ahead of schedule and under budget versus costly delays and complications. With rental costs for specialized cranes ranging from $1,000 to $15,000 per day, making an informed choice is essential for your bottom line.

In 2025, several key trends are reshaping the crane rental landscape. Sustainability concerns have driven innovation in electric and hybrid models, reducing emissions without sacrificing power. Meanwhile, technological advancements including AI-assisted operation, remote monitoring capabilities, and enhanced safety features are transforming how these machines function on job sites. The post-pandemic construction surge has also created new demand patterns, making certain types of cranes more difficult to secure without advance planning.

Whether you’re managing a high-rise development in an urban center, expanding infrastructure in challenging terrain, or handling specialized industrial installations, understanding your crane options is essential. This guide examines the seven most versatile and in-demand types of cranes for 2025, helping you navigate the rental market with confidence.

The Top 7 Types of Cranes for 2025 Rentals

Below is a quick reference—detailed insights follow.

| Crane Type | 2025 Rental Appeal | Best For |

| All‑Terrain Cranes | Hybrid/electric models (eco-friendly, low emissions) | Roadwork, Remote Projects |

| Tower Cranes | Modular designs (faster installation, space-saving) | Urban High‑Rise Construction |

| Crawler Cranes | Reduced ground pressure for sensitive sites | Wind Turbine Installations |

| Rough‑Terrain Cranes | Enhanced stability tech for uneven ground | Oil/Gas Projects, Rural Areas |

| Telescopic Truck Cranes | AI‑assisted load monitoring | Quick Set‑Ups in Logistics/Warehousing |

| Overhead Bridge Cranes | Factory automation integration (predictive maintenance) | Manufacturing, Assembly Lines |

| Floating Cranes | Adapted for offshore energy projects | Port Expansions, Offshore Wind Farms |

1. All-Terrain Cranes

All-terrain cranes represent the pinnacle of versatility in modern construction equipment, designed to navigate both highways and challenging off-road conditions with equal capability. These powerful machines have evolved significantly for 2025, addressing the construction industry’s growing need for equipment that can adapt to diverse project environments without sacrificing lifting capacity.

What They Are: All-terrain cranes feature multiple axles (typically 4-12) with all-wheel drive and all-wheel steering capabilities, mounted on a specialized carrier. This design allows them to travel efficiently on highways at speeds up to 55 mph, then transition seamlessly to rough, unprepared terrain at job sites. Their telescopic booms, which can extend up to 200 feet on standard models and over 300 feet on larger variants, provide impressive vertical reach without requiring time-consuming assembly.

The engineering behind these cranes reflects a careful balance between mobility, power, and stability. Most all-terrain cranes offer lifting capacities ranging from 40 to 1,200 tons, making them suitable for a wide spectrum of projects. What truly distinguishes them is their adaptability – with the ability to maneuver through tight urban spaces one day and traverse muddy, uneven ground at remote sites the next.

2025 Rental Appeal: This year has seen a remarkable transformation in the all-terrain crane segment, with hybrid and electric models gaining significant market share. The Liebherr LTC 1050-3.1E and the Tadano ATF-60G-3, among others, now offer zero-emission operation modes for environmentally sensitive urban projects while maintaining traditional power options for extended operation in remote locations without charging infrastructure.

These eco-friendly models command approximately a 15-20% premium in rental costs, but increasingly, projects with green building certification requirements are making them mandatory. Additionally, many urban centers have introduced emissions restrictions that give preferential treatment to hybrid equipment, making these models especially valuable for city-based work.

Another compelling advancement is the integration of autonomous positioning systems that use GNSS technology to optimize crane setup. These systems automatically analyze ground conditions, boom configurations, and load requirements to suggest the most efficient and safe positioning. For rental customers, this translates to reduced setup time and minimized risk, particularly for less experienced operators.

Best For: All-terrain cranes excel in projects that involve frequent relocation or challenging access conditions. Highway expansion and bridge rehabilitation work benefit from their ability to drive directly to multiple work points without requiring separate transport equipment. Their compact footprint relative to their lifting capacity makes them ideal for congested urban renewal projects where space is at a premium.

Remote construction sites, particularly those in mountainous regions or areas with limited infrastructure, represent another perfect application. The self-contained nature of these cranes eliminates the need for separate assembly equipment, reducing the logistical complexity of projects in isolated locations.

In 2025, rental rates for all-terrain cranes typically range from $3,000 to $12,000 per day, depending on size and capabilities. While this represents a premium over some other crane types, the operational flexibility and reduced need for supporting equipment often results in overall project savings when total costs are considered.

2. Tower Cranes

Tower cranes have become synonymous with urban development, their distinctive silhouettes defining city skylines during periods of growth. In 2025, these vertical giants have evolved significantly from their predecessors, incorporating revolutionary technologies that address the unique challenges of modern high-rise construction.

What They Are: Tower cranes feature a vertical mast topped with a rotating horizontal jib (the working arm) and counter-jib (which holds counterweights). This configuration provides exceptional height capabilities while maintaining a relatively small footprint at ground level – a crucial advantage in congested urban environments. Modern tower cranes achieve heights exceeding 800 feet while delivering lifting capacities from 5 to 240 tons, depending on the model and configuration.

Unlike mobile cranes, tower cranes remain fixed in position for the duration of a project, either anchored to a concrete foundation or attached to the building structure itself using specialized bracing systems. Their operation relies on electric motors rather than internal combustion engines, making them inherently quieter and producing zero on-site emissions – an increasingly important consideration for urban construction.

Tower cranes fall into several sub-categories, including:

- Hammerhead cranes (with horizontal jibs)

- Luffing jib cranes (with angled jibs that can be raised to avoid obstacles)

- Self-erecting tower cranes (smaller units that can set themselves up)

- Climbing cranes (which can elevate themselves as a building grows taller)

2025 Rental Appeal: The most significant development in the tower crane market for 2025 is the widespread adoption of modular design principles. Modern tower cranes feature standardized sections that can be transported in standard shipping containers and assembled quickly on site using smaller mobile cranes. This modular approach has reduced installation time by up to 40% compared to traditional methods, translating to substantial savings in project timelines and rental costs.

Digital twin technology has also transformed tower crane operations. Before physical installation, rental companies now create detailed virtual simulations of the crane’s operation within the specific project environment. These simulations identify potential collision points, optimize lifting paths, and determine ideal positioning, eliminating costly adjustments after installation.

Rental companies are increasingly offering tower cranes with integrated smart systems that provide real-time monitoring of structural integrity, wind loads, and operator actions. These systems can automatically restrict operation when conditions exceed safe parameters and maintain detailed logs for compliance and safety documentation.

Best For: Tower cranes remain the undisputed champions for high-rise construction in dense urban environments. Their combination of vertical reach, lifting capacity, and minimal ground footprint makes them essential for projects where space is limited but vertical requirements are substantial. Modern residential and commercial skyscrapers, especially those exceeding 30 stories, almost universally rely on tower cranes during construction.

They also excel in projects with extended timelines, where the initial setup costs can be distributed across months or years of continuous use. Major infrastructure developments like hospital complexes, convention centers, and sports stadiums frequently employ multiple tower cranes working in coordinated patterns to maximize efficiency.

Rental rates for tower cranes in 2025 typically follow a different structure than mobile cranes, with monthly rates ranging from $15,000 to $50,000, plus installation costs of $50,000 to $200,000 depending on size and complexity. While these figures may seem substantial, the efficiency gains for appropriate projects more than justify the investment.

3. Crawler Cranes

Crawler cranes represent the heavy lifters of the construction industry, combining tremendous lifting capacity with the ability to maneuver while carrying loads. In 2025, these powerful machines have become increasingly sophisticated, incorporating advanced technologies that enhance their traditional strengths while addressing historical limitations.

What They Are: Crawler cranes are characterized by their continuous track undercarriage – similar to those found on tanks and bulldozers – which distributes their substantial weight across a larger surface area. This design enables them to traverse soft or uneven ground while maintaining stability, even when carrying significant loads. Unlike wheeled mobile cranes, crawler cranes can often move with a load suspended, though at reduced speeds and with careful planning.

These cranes typically employ lattice booms rather than telescopic systems, constructed from triangular framework sections that can be added or removed to adjust reach. Modern crawler cranes offer lifting capacities ranging from 50 to over 3,500 tons and can achieve hook heights exceeding 500 feet when configured with luffing jibs. This combination of power and reach makes them indispensable for the heaviest lifting requirements in construction and industrial settings.

The tradeoff for this impressive capability is transportation complexity. Crawler cranes must be disassembled into multiple components for highway transport and then reassembled on-site, a process that can require days and substantial supporting equipment. This makes them less economical for short-duration projects or those requiring frequent relocation.

2025 Rental Appeal: The most significant advancement in crawler crane technology for 2025 has been the development of low ground pressure (LGP) undercarriage systems. These wider tracks distribute the crane’s weight more effectively, reducing ground bearing pressure by up to 40% compared to traditional designs. This innovation has expanded the usable range of crawler cranes to include environmentally sensitive areas, wetlands, and sites with poor soil conditions that previously required extensive and costly ground preparation.

Modular counterweight systems have also transformed the rental landscape for crawler cranes. These systems allow precise ballasting configurations tailored to specific lift requirements, optimizing both safety and efficiency. Rather than renting a larger crane than necessary to ensure adequate stability, contractors can now configure exactly the counterweight needed for each phase of a project, potentially reducing rental costs by 15-25% through right-sizing.

Advanced telematics and load management systems now standard on rental crawler cranes provide operators with comprehensive real-time data including ground pressure mapping, structural stress analysis, and 3D working range limitations. These systems not only enhance safety but also create detailed digital records that simplify regulatory compliance and insurance documentation.

Best For: Crawler cranes excel in heavy infrastructure and energy sector applications where extreme lifting capacity is essential. Wind turbine installation has become one of their primary applications, with specialized models designed specifically for handling the massive components of modern turbines, which can weigh over 100 tons and require placement at heights exceeding 400 feet.

Bridge construction represents another ideal application, particularly for concrete segmental bridges where massive precast sections must be precisely positioned. The ability to traverse parallel to the developing structure while carrying loads makes crawler cranes uniquely suited to this work.

Industrial plant construction and modernization, particularly in the petrochemical, power generation, and manufacturing sectors, heavily relies on crawler cranes for installing heavy equipment including reactors, generators, and processing vessels. Their ability to lift massive loads in confined spaces with limited supporting infrastructure often makes them the only viable option for these specialized applications.

Rental rates for crawler cranes in 2025 typically range from $5,000 to $30,000+ per day, depending on capacity and configuration. While these rates exceed those of most other crane types, the unmatched lifting capabilities and reduced need for ground preparation often result in overall project savings for appropriate applications.

4. Rough-Terrain Cranes

Rough-terrain cranes represent the workhorses of challenging construction environments, combining mobility in difficult conditions with impressive lifting capabilities. For 2025, these versatile machines have undergone significant evolutions that enhance their core strengths while expanding their application range.

What They Are: Designed specifically for off-road operation, rough-terrain cranes feature oversized tires, all-wheel drive, and purpose-built suspensions that enable them to navigate unpaved surfaces, inclines, and obstacles that would immobilize standard cranes. Their compact dimensions – typically shorter and narrower than all-terrain alternatives – allow them to maneuver through tight spaces while maintaining impressive stability during lifting operations.

Unlike larger crane varieties that require separate transportation, rough-terrain cranes can travel short distances under their own power at speeds up to 30 mph, though they are not designed for highway use and must be transported between distant sites via flatbed trailers. Their telescopic booms extend from 70 to 150 feet depending on the model, with lifting capacities typically ranging from 30 to 160 tons.

The control systems in rough-terrain cranes are optimized for precise operation in challenging conditions, with multi-position outriggers that can be configured asymmetrically to adapt to irregular terrain while maintaining load stability. This flexibility makes them particularly valuable in environments where perfectly level, stable ground is unavailable.

2025 Rental Appeal: The most significant advancement in rough-terrain cranes for 2025 has been the widespread implementation of adaptive stability technology. These sophisticated systems continuously monitor ground conditions, outrigger pressure, boom position, and load dynamics to create real-time stability envelopes. Unlike previous generations that relied on predetermined lifting charts based on ideal conditions, these adaptive systems accurately calculate actual lifting capacity based on the specific configuration and conditions at each moment.

This technology has dramatically improved both safety and efficiency, enabling operators to utilize the crane’s full capability even on severely uneven terrain while maintaining appropriate safety margins. For rental customers, this translates to the ability to use smaller, more economical crane models for jobs that previously would have required oversized equipment to ensure stability.

Another notable innovation has been the integration of terrain mapping systems that use LIDAR and visual sensors to create detailed 3D representations of the working environment. These systems help operators identify potential obstacles, plan movement paths, and position the crane optimally without requiring ground crew assistance – a particularly valuable feature for projects in remote or hazardous locations.

Best For: Rough-terrain cranes excel in resource extraction settings including oil and gas fields, mining operations, and quarries, where unprepared surfaces and challenging geography are standard conditions. Their ability to navigate between multiple work points without requiring disassembly or separate transportation makes them ideal for these environments, where work often progresses incrementally across large areas.

Rural infrastructure projects, particularly power line installation, cell tower construction, and water system development, heavily utilize rough-terrain cranes. These projects frequently involve work in undeveloped areas with limited access roads and variable ground conditions – precisely the environment these machines are designed to handle.

Disaster response and recovery operations have increasingly relied on rough-terrain cranes, where their ability to operate in areas with damaged infrastructure and unstable ground conditions provides capabilities that other equipment cannot match. Their relative ease of transport and quick setup time make them particularly valuable in emergency situations where rapid deployment is essential.

Rental rates for rough-terrain cranes in 2025 typically range from $1,800 to $5,500 per day, positioning them as a more economical option than all-terrain or crawler cranes for appropriate applications. Their specialized capabilities make them particularly cost-effective for projects in challenging terrain, where the alternatives would involve either extensive ground preparation or substantially larger equipment.

5. Telescopic Truck Cranes

Telescopic truck cranes represent the perfect balance of mobility and lifting capability, making them among the most widely used crane types across diverse industries. For 2025, these versatile machines have incorporated cutting-edge technologies that significantly enhance their operational efficiency and safety.

What They Are: Built on commercial truck chassis modified for crane operations, telescopic truck cranes combine road-legal transportation with substantial lifting capability. Their defining feature is the hydraulically extendable telescopic boom, which nests multiple sections inside one another when retracted for transport, then extends to provide reach heights from 90 to over 200 feet depending on the model. This design allows for rapid deployment without the assembly requirements of lattice boom alternatives.

Most telescopic truck cranes offer lifting capacities between 40 and 200 tons, with outriggers that extend from the chassis to provide stability during lifting operations. Unlike dedicated off-road crane types, these machines can travel at highway speeds (typically up to 65 mph) and comply with standard road regulations when in transport configuration, eliminating the need for separate transportation equipment for site-to-site movement.

The truck-mounted design creates a highly efficient dual-purpose vehicle that can serve as both transportation and lifting equipment, reducing the total equipment footprint required on job sites. Modern designs feature carrier cabs for highway travel and separate operator cabs mounted on the superstructure for precise control during lifting operations.

2025 Rental Appeal: The most revolutionary development in the telescopic truck crane segment for 2025 has been the integration of AI-assisted load monitoring systems. These advanced technologies use multiple sensor arrays combined with machine learning algorithms to analyze load dynamics in real-time, detecting potential instability conditions before they become dangerous. The systems can provide proactive guidance to operators, automatically restrict movements that could compromise stability, and maintain comprehensive digital records of all operations for safety compliance and training purposes.

For rental customers, these systems provide both enhanced safety and increased productivity, as they allow less experienced operators to work more efficiently while maintaining appropriate safety margins. The predictive nature of these systems helps prevent the overcautious operation that often characterizes less experienced crane handlers, optimizing the productive capacity of the equipment.

Another significant advancement has been the development of quick-change counterweight systems that can be configured in minutes rather than hours. These systems allow rental customers to rapidly adapt the crane for different lifting requirements throughout a project, optimizing both safety and fuel efficiency by carrying only the necessary ballast for each specific task.

Best For: Telescopic truck cranes excel in applications requiring mobility between multiple lifting locations. Commercial and light industrial construction projects typically utilize these cranes for steel erection, precast concrete placement, and mechanical equipment installation, where their ability to quickly relocate between lifting points maximizes productivity.

Logistics and warehousing operations frequently employ telescopic truck cranes for equipment installation, relocation, and maintenance, particularly in facilities where production equipment must be periodically replaced or reconfigured. Their ability to travel directly to the site without specialized transportation makes them ideal for these time-sensitive operations.

Telecommunications infrastructure development has become a major application for telescopic truck cranes, particularly for cell tower construction and equipment upgrades. The combination of vertical reach, precision placement capability, and highway mobility makes them perfectly suited for this growing sector, where work typically involves multiple sites spread across wide geographic areas.

Rental rates for telescopic truck cranes in 2025 typically range from $2,200 to $8,000 per day, depending on capacity and boom length. While these figures exceed those of smaller mobile cranes, the operational efficiency and reduced support equipment requirements often result in lower total project costs for appropriate applications.

6. Overhead Bridge Cranes

Overhead bridge cranes represent the backbone of modern manufacturing and warehousing operations, providing consistent lifting capabilities across fixed workspaces. In 2025, these industrial workhorses have undergone a technological renaissance, incorporating smart systems that dramatically enhance their utility in automated production environments.

What They Are: Unlike mobile cranes designed for construction applications, overhead bridge cranes are permanently installed systems consisting of parallel runways supporting a traveling bridge that spans the work area. The hoist mechanism traverses along this bridge, creating a three-dimensional operating envelope that typically covers the entire floor space below. This design enables precise load movement in three axes (length, width, and height) throughout a defined workspace.

Overhead bridge cranes feature lifting capacities ranging from 1 to over 400 tons, with spans from 20 to 150 feet depending on the facility requirements. Their fixed installation provides exceptional stability and positioning accuracy, making them ideal for repetitive lifting operations where consistency is essential. Unlike mobile cranes, they require no setup time between lifts and can operate continuously, dramatically increasing throughput for high-volume applications.

These systems typically operate using electric motors rather than internal combustion engines, eliminating emissions concerns and reducing noise – critical advantages for indoor industrial settings. Their control systems range from simple pendant controllers operated by workers on the floor to sophisticated remote control systems and, increasingly, fully automated operation integrated with facility production management systems.

2025 Rental Appeal: While traditionally purchased as permanent infrastructure, the overhead bridge crane rental market has expanded significantly in 2025, driven by the proliferation of modular, semi-permanent systems designed specifically for the rental market. These systems can be installed in existing buildings without structural modifications, using self-supporting frameworks that distribute loads to the floor rather than requiring reinforced ceiling attachment points. This innovation has made overhead crane capabilities accessible to facilities with short-term or seasonal needs without requiring capital investment.

The most significant technological advancement in the overhead crane segment has been the integration of automation systems compatible with Industry 4.0 manufacturing environments. Modern rental units come equipped with programming interfaces that allow seamless integration with production scheduling systems, enabling coordinated operation with robotic assembly equipment, automated guided vehicles, and inventory management platforms. For manufacturers implementing flexible production lines, these rental systems provide lifting capabilities that can adapt to changing production requirements without permanent infrastructure commitments.

Advanced load sensing and positioning systems have also transformed the rental appeal of overhead cranes. Using computer vision and LIDAR technology, these systems can identify and track specific components, automatically adjust lifting parameters based on recognized load characteristics, and maintain precise positioning records for quality control purposes. These capabilities are particularly valuable in regulated industries including aerospace, pharmaceutical manufacturing, and medical device production, where process documentation requirements are stringent.

Best For: Manufacturing plants undergoing modernization or expansion represent the primary market for overhead bridge crane rentals. These facilities often require temporary lifting capabilities during renovation phases or need to evaluate new production arrangements before committing to permanent infrastructure. The ability to install, reconfigure, and remove these systems without structural modifications provides valuable flexibility during transition periods.

Assembly lines for large products including vehicles, agricultural equipment, and industrial machinery benefit from overhead crane systems that can move heavy components precisely through sequential workstations. Rental options are particularly appealing for contract manufacturing operations where production requirements may change significantly between projects.

Warehousing and distribution centers handling oversized or non-standard items that exceed the capabilities of conventional material handling equipment frequently utilize overhead crane systems. The growing trend toward short-term warehouse leasing for seasonal inventory management has created significant demand for rental crane systems that can be deployed and removed as needed.

Rental rates for overhead bridge cranes in 2025 typically follow monthly structures ranging from $8,000 to $25,000, plus installation and removal costs. While these figures exceed short-term mobile crane rentals, the continuous availability and specialized capabilities make them economical for appropriate industrial applications extending beyond a few weeks.

7. Floating Cranes

Floating cranes represent the specialized titans of marine construction and offshore operations, bringing massive lifting capabilities to water-based projects where conventional land-based equipment cannot operate. In 2025, these specialized machines have gained renewed importance due to the explosive growth in offshore energy development and port infrastructure expansion.

What They Are: Floating cranes consist of powerful lifting equipment mounted on barges, pontoons, or purpose-built vessels designed to provide stability in marine environments. Unlike their land-based counterparts, these cranes must contend with the dynamic challenges of water-based operation, including wave action, tidal fluctuations, and the inherent instability of floating platforms. Sophisticated ballast systems and specialized hull designs work together to maintain stability during lifting operations.

These marine specialists come in several distinct configurations:

- Sheerleg cranes with fixed-angle booms optimized for maximum lifting capacity

- Revolving floating cranes with 360-degree slewing capabilities

- Semi-submersible crane vessels that can partially submerge for enhanced stability during heavy lifts

- Specialized jack-up platforms that anchor themselves to the seabed during lifting operations

Lifting capacities range from 100 tons for harbor construction units to over 10,000 tons for specialized offshore vessels used in energy sector applications. Operating depths vary similarly, from shallow-water harbor units to deep-water systems capable of working at oceanic depths exceeding 10,000 feet.

2025 Rental Appeal: The floating crane rental market has experienced unprecedented growth in 2025, driven primarily by the global expansion of offshore wind energy development. The latest generation of floating cranes has been specifically designed to handle the massive components of modern wind turbines, including monopiles weighing up to 3,000 tons and nacelles positioned at heights exceeding 500 feet above water level. These specialized vessels incorporate dynamic positioning systems that maintain precise location during installation without requiring traditional anchoring, dramatically reducing setup time and expanding the viable weather windows for operation.

Advanced motion compensation systems represent another significant advancement in the floating crane segment. These sophisticated hydraulic systems automatically adjust to counteract wave action and vessel movement, maintaining precise positioning of loads even in challenging sea conditions. For rental customers, this translates to reduced weather delays and expanded operating seasons, particularly in regions with historically restrictive weather limitations.

The integration of underwater visualization systems has also transformed the capabilities of floating cranes. Modern units employ ROV (remotely operated vehicle) systems and sonar imaging to provide operators with clear views of underwater operations, enabling precise placement of subsea components without requiring diver assistance. This technology has proven particularly valuable for artificial reef construction, underwater pipeline installation, and foundation work for offshore structures.

Best For: Offshore wind farm development has emerged as the dominant application for floating crane rentals in 2025. The accelerating transition to renewable energy has created unprecedented demand for these specialized vessels, with projects frequently requiring multiple units working in coordinated patterns to maximize efficiency during the limited weather windows available in many regions. The largest projects may keep floating cranes on site for months or even years during phased development.

Port expansion and modernization projects represent another major market for floating crane rentals. The global shipping industry’s transition to ever-larger vessel classes has necessitated widespread harbor deepening, breakwater construction, and terminal expansion. Floating cranes play essential roles in these projects, handling massive precast concrete elements, placing riprap for erosion protection, and installing modern dock equipment.

Offshore oil and gas decommissioning has created significant demand for specialized floating cranes capable of dismantling and removing aging platforms. Environmental regulations increasingly require complete removal of decommissioned structures, creating complex lifting challenges as components designed for permanent installation must be safely separated and recovered. The specialized rigging expertise provided with floating crane rentals is particularly valuable for these technically demanding operations.

Rental rates for floating cranes in 2025 follow different structures than land-based equipment, typically ranging from $50,000 to $250,000+ per day for the largest units, including specialized crew and support vessels. While these figures represent the highest costs in the crane rental spectrum, the specialized capabilities and limited availability of these machines make them essential investments for appropriate marine projects.

How to Choose the Right Type of Crane for Your 2025 Project

Selecting the optimal crane for your project extends far beyond simply matching lifting capacity to your heaviest load. In 2025’s increasingly complex construction environment, a systematic approach to crane selection can deliver substantial benefits in efficiency, safety, and cost control. The following comprehensive framework will guide you through the critical decision points:

Project Assessment Checklist

Load Analysis:

- Maximum weight requirements (including all rigging equipment)

- Dimensions and center of gravity for critical loads

- Lift frequency and duration

- Special handling requirements (fragile, hazardous, or irregularly shaped items)

Site Evaluation:

- Ground conditions and bearing capacity

- Available footprint for crane positioning and outrigger deployment

- Overhead restrictions (power lines, adjacent structures, trees)

- Underground utilities and infrastructure

- Access routes for crane delivery and setup

- Weather conditions and seasonal variations

Operational Parameters:

- Required working radius (horizontal distance from crane center to load)

- Maximum hook height needed

- Duration of crane requirement (days, weeks, months)

- Frequency of repositioning during project

- Working environment (urban, industrial, marine, etc.)

- Noise or emissions restrictions at the site

Project Economics:

- Available budget for crane rental

- Cost implications of project delays

- Value of accelerated completion

- Labor costs for assembly/disassembly

- Transport logistics and associated expenses

2025 Considerations for Crane Selection

The crane rental landscape has evolved significantly in 2025, with several new factors warranting careful consideration during the selection process:

Sustainability Requirements: Environmental considerations have moved from peripheral concerns to central decision factors for many projects. Many urban centers now impose strict emissions regulations, while projects seeking green building certifications must document equipment emissions throughout construction. When consulting with rental providers, inquire specifically about:

- Availability of electric, hybrid, or Tier 5 diesel models

- Documented emissions data for carbon reporting

- Noise output levels (particularly crucial for urban projects)

- Engine idle reduction technologies

- Renewable fuel compatibility

The premium for eco-friendly options has decreased substantially in 2025, with many projects finding that the 10-15% higher rental costs are offset by avoiding regulatory compliance issues and qualifying for expedited permitting in environmentally sensitive areas.

Technology Integration: Modern crane telematics and operational technologies can dramatically improve project efficiency when properly leveraged. Key systems to discuss with rental providers include:

- Load moment indicators with data logging capabilities

- GPS-based positioning systems for multi-crane coordination

- Remote monitoring platforms for project management visibility

- Automated safety envelope restrictions for high-risk areas

- Integration capabilities with Building Information Modeling (BIM) systems

- Operator assistance technologies (collision avoidance, precision placement)

These technologies typically add 5-8% to base rental costs but can reduce overall project expenses through improved efficiency and reduced risk of accidents or operational delays.

Operator Availability: The skilled labor shortage affecting the construction industry has made operator availability a critical consideration for crane selection in 2025. When evaluating options:

- Confirm whether qualified operators are included with the equipment rental

- Assess the availability of operators certified for specialized equipment

- Consider the learning curve for unfamiliar crane types

- Evaluate remote operation options for standardized lifts

- Review operator fatigue management for extended duration projects

Some rental providers now offer virtual reality training programs that can qualify existing team members for operation of specific crane models, potentially reducing dependency on scarce external operators for less complex applications.

Maintenance and Support: Extended project timelines increase the importance of reliable service support from rental providers. Essential questions include:

- Preventive maintenance schedules and impact on operations

- Response time guarantees for emergency service

- Availability of critical replacement parts

- Remote diagnostics capabilities

- Backup equipment availability

Leading rental providers now offer predictive maintenance programs that utilize real-time monitoring to address developing issues before they cause operational disruptions, dramatically reducing unplanned downtime.

Expert Guidance for Optimal Selection

The complexity of modern crane selection warrants consultation with specialists who can help navigate these interconnected decision factors. When engaging with rental providers, request comprehensive analysis of:

- Total Cost Modeling: Beyond daily or monthly rental rates, request detailed projections of all associated costs including transportation, assembly/disassembly, operator expenses, fuel/energy consumption, and potential efficiency impacts on other project elements.

- Risk Assessment: Professional evaluation of site-specific challenges and appropriate equipment specifications to address them, potentially identifying risks not evident in general project planning.

- Scheduling Optimization: Expert insight on crane availability windows, lead time requirements, and coordination with project milestones to minimize costly idle periods while ensuring equipment is available when needed.

- Regulatory Compliance: Verification that selected equipment meets all local regulations regarding emissions, noise, operator certification, and safety requirements specific to your project location.

- Alternative Solutions: Creative approaches including combination strategies using multiple smaller cranes instead of a single large unit, specialized attachments that expand equipment capabilities, or scheduling adjustments to optimize equipment utilization.

The most valuable rental partners in 2025 position themselves as solution providers rather than equipment suppliers, offering expertise that extends beyond their machine catalog to address your specific project challenges. This consultative approach often identifies opportunities for substantial cost savings that more than offset any premium for specialized equipment or services.

Future Trends in Crane Rentals (2025 and Beyond)

- AI & IoT Integration: Predictive maintenance via onboard sensors reduces unplanned downtime—over 30% fewer breakdowns reported at smart job sites Fact.MR.

- Electric & Hydrogen Powertrains: Manufacturers like Liebherr are testing hydrogen‑fuel cell cranes to eliminate onsite emissions.

- Autonomous Operation: Drone‑assisted surveys and semi‑autonomous lifts are piloting in Europe and North America.

Projected Market Growth

See the bar chart below illustrating the projected global crane rental market size from 2024 to 2029.

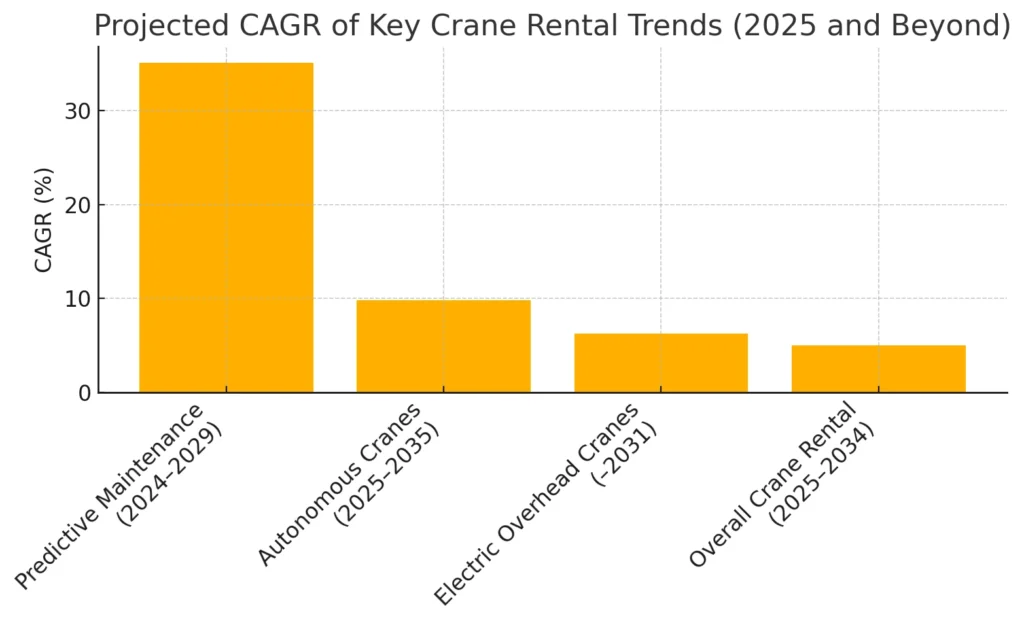

The bar chart above illustrates the projected compound annual growth rates (CAGRs) for key “Future Trends in Crane Rentals (2025 and Beyond)”:

- Predictive Maintenance (Global Predictive Maintenance Market: USD 10.6 B in 2024 → USD 47.8 B by 2029): 35.1% CAGR MarketsandMarkets

- Autonomous Cranes (USD 3.404 B in 2025 → USD 8.67 B by 2035): 9.8% CAGR Future Market Insights

- Electric Overhead Cranes (USD 3.29 B by 2031): 6.3% CAGR GlobeNewswire

- Overall Crane Rental Industry (USD 50.63 B in 2024 → USD 82.39 B by 2034): 5.0% CAGR Future Market Insights

This visualization highlights how predictive maintenance (driven by IoT/AI) is set to outpace other segments, underscoring its critical role in reducing downtime and optimizing fleet operations. Autonomous and electric‑powered crane segments also show robust growth, reflecting industry shifts toward automation and sustainability.

Conclusion

Selecting the right types of cranes in 2025 means balancing capacity, site conditions, sustainability, and setup speed. Whether you need the reach of a tower crane or the versatility of an all‑terrain model, rental fleets have never been more advanced. Partner with experts—like those at United Rentals—to tailor the perfect crane solution for your next project.

FAQ Section

Q: What type of crane is cheapest to rent for small projects?

Ans: Telescopic truck cranes often offer the best hourly rates and rapid setup for loads under 50 tons, making them cost‑effective for smaller jobs.

Q: Which types of cranes are best for eco‑conscious job sites?

Ans: All‑terrain hybrid/electric cranes and hydrogen prototype cranes provide zero‑emission lifts, aligning with green building standards.